The Studio

From a single piece to a large series

With the well-equipped AND_i4U workshop, we can quickly respond to short-term requests and produce one-offs or prototypes ourselves, which is important in this industry.

Years of experience with a great deal of different needs and customer wishes, tailored to the materials, techniques and production facilities to get the best quality products.

We can offer everything from single items to mass production.

On request, we also take care of a noble branded packaging for your product.

You want to see your product staged? We take care of the photo and / or video production. We have an extremely professional network that includes everything from photographers, video team, stylists, grooming, modeling agencies, location scouting to photoequipement.

What is possible?

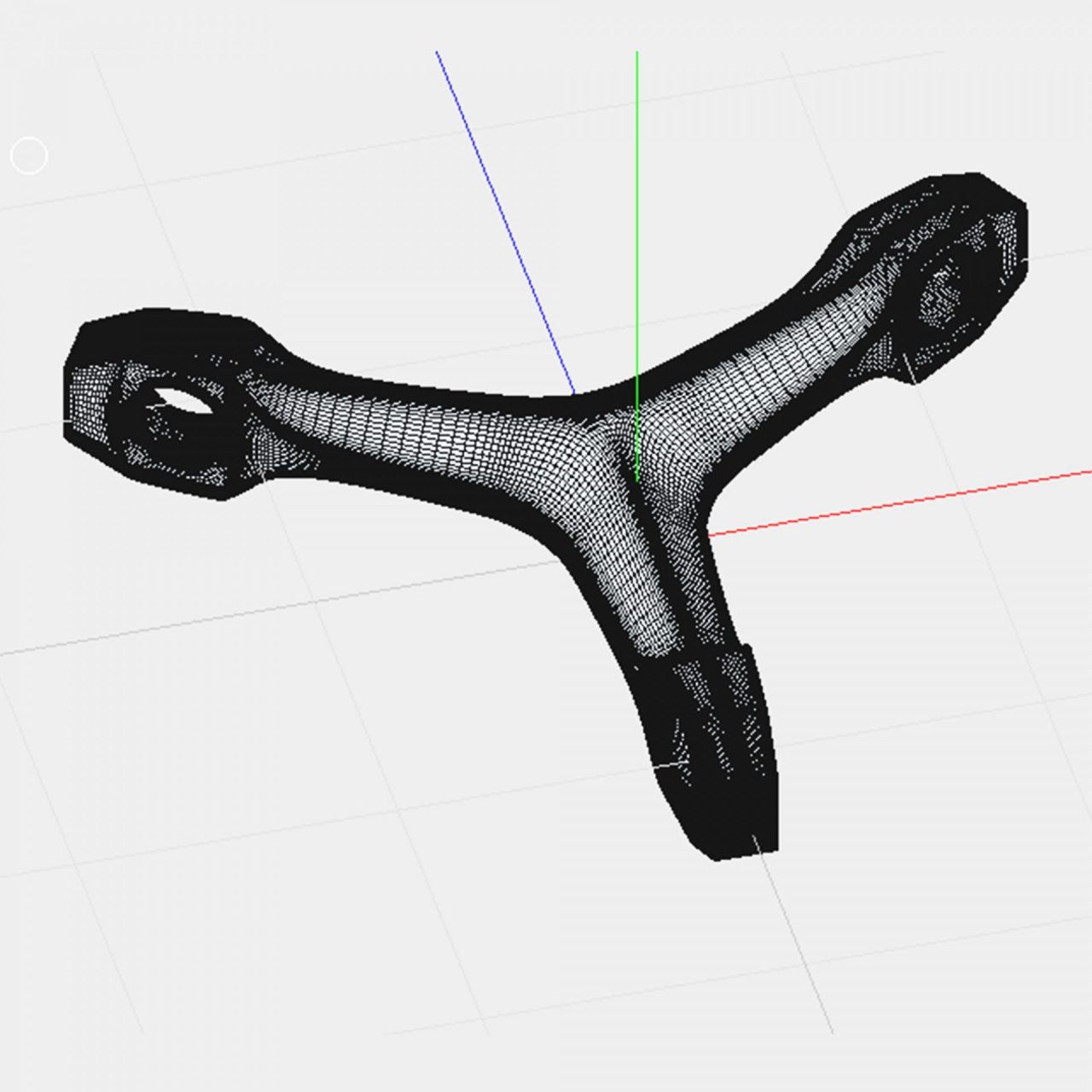

Depending on the customer’s request and design prototypes are either modeled by hand / carved, or created digitally and then milled with CNC, or 3D plotted.

We can offer everything from single items to mass production.

You come to us – with a rough vision:

We take care of the concept, design, prototyping, pre-production and implementation.

You come to us – with a concrete idea, just need the implementation:

We take care of prototyping and production management or implementation, if necessary.

We have production partners in Austria, Germany and Thailand. We do not produce in politically incorrect countries, we do not earn money because of the suffering of other peoples. We do not want to destroy our planet Earth.

To meet all customer needs, we use a variety of materials and techniques:

The most commonly used materials are anodized aluminum, bronze and brass galvanized, bioplastic, leather.

These materials have different abilities, such as:

specific weight: some pieces have to be particularly light due to eg wearability, comfort or size, other pieces in turn have to have a certain weight due to strength, quality, technical procedures.

Conductivity: mechanically machined aluminum can be wonderfully anodized in almost all colors, aluminum casting, for example, becomes more noble when it is specially painted or powder-coated. Bronze or brass can be galvanically rhodium plated, gold plated, nickel plated.

Haptic: Through processing methods such as polishing, vibratory grinding, glass bead blasting, scratching, brushing, satin finishing, … surfaces can be created with completely different haptics. Additional treatments such as anodizing, chemical etching, car painting, powder coatings, etc. expand the possibilities.

Elasticity and rigidity: organic plastics are extremely easy to model and pour, with the advantage that thinner wall thicknesses keep them slightly elastic.

For all products that require a certain rigidity, we work with metal.